Originally paper was made in Britain from linen and cotton rags: old clothes were the main source. The rags had to be sorted and shredded and were then washed before transfer to a water-filled tub, and beaten into a pulp. The pulp was then diluted with water to the correct consistency. the sheets of paper were created from the pulp by a ‘vatman’ who dipped a square mould with a wire-meshed bottom into the pulp. On removing it, he would shake it carefully to spread the fibres evenly and drain off surplus water, and pass it to a ‘coucher’ who turns out the wet sheet onto a felt blanket, creating a stack of felted sheets. The stack would then be put into a to a press to force out the surplus water, before the sheets were separated out and hung to dry in a loft. When dry, the paper would be treated (or ‘sized’ depending on the use to which it would be put, before being pressed, cut and packaged for the customer.

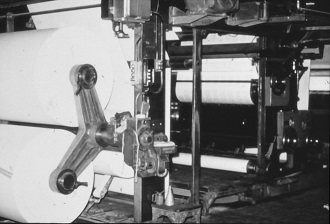

In the 1790s the Fourdrinier brothers invented the mechanised process for paper-making. The fluid pulp flows onto a continuously moving wire mesh. The water is gradually removed, and the fibres evenly spread, before the paper is dried, wound onto a reel (known as a web) and cut into sheets. Demand for linen and cotton rags outstripped supply so other materials such as wood pulp and esparto grass, were tried. From the mid-nineteenth century printing machines that could be fed directly from the reel of paper were developed.

The British bulk measures for paper in sheets were: a quire (24 sheets); a ream (516 sheets); a bundle (2 reams); a bale (5 reams). The measurements for each size can be found here.

Information on the history of papermaking in the Edinburgh can be found on the following websites

- 300 years of papermaking in Penicuik

- From pulp to print: archive material at Heriot-Watt University

Papermaking at Caldercruix in Lanarkshire is described on the Culture NL website: Rags to riches.

Other useful links about papermaking:

- resources for schools prepared by the Confederation of Paper Industries

- British Association of Paper Historians

SPRAT is grateful for support from The Watson Foundation

SPRAT is grateful for support from The Watson Foundation