As reported in the Strathearn Herald of Saturday July 6, 1907, the Cossar press was:

so named after its patentee, a young Scotsman, with a genius for mechanics, Mr T Cossar, Govan Press […] embodies the latest improvements in printing off a flat bed of type, and with a roll of paper instead of cut sheets. The paper after being printed is cut off the reel, folded and delivered ready for sale at a speed of 4000 to 5000 per hour.

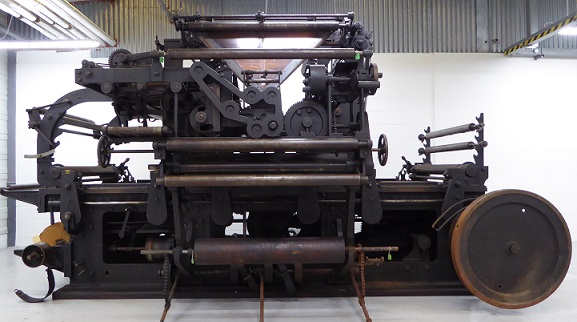

The ‘Cossar Patent Flat Bed Web Newspaper Printing Machine’ was built into the premises of David Philips Printers, Comrie Street, Crieff, under the supervision of its Scottish designer in 1907. It is thought to be the last remaining example of the original design in the world, and the oldest reel-fed flatbed newspaper printing press in Britain still in working order. It was used to print the local weekly newspaper, Strathearn Herald, every single week from the original installation of this machine until 28 March 1991, when the title was transferred to Scottish and Universal Newspapers (now part of Trinity Mirror plc).

The Crieff Cossar is an important part of the Scottish printing industry’s technological and industrial heritage: the Scottish Printing Archival Trust lobbied for it to be saved from scrap, and led the fundraising effort to ensure its future. The Trust is grateful for the generous support from the National Printing Heritage Trust, the Scottish Newspaper Society, Unite the Union, the Oxford Guild of Printers and individual donors.

The Crieff Cossar is an important part of the Scottish printing industry’s technological and industrial heritage: the Scottish Printing Archival Trust lobbied for it to be saved from scrap, and led the fundraising effort to ensure its future. The Trust is grateful for the generous support from the National Printing Heritage Trust, the Scottish Newspaper Society, Unite the Union, the Oxford Guild of Printers and individual donors.

Because of the constraints on access, it could only be removed from the premises in Crieff as it was installed — in pieces. There is a page of images showing how complex this was. It was rebuilt but remained in temporary storage in Govan, near its inventor’s childhood home before a final move to National Museums Scotland’s Collection Centre in Edinburgh. A ‘Cossar Club’ was established to bring together individuals interested in the press.

In the 1890s, Tom Cossar was experimenting with adaptations to the ‘Wharfedale’ flat-bed presses used in the family business, John Cossar & Son. The firm had its origins in the 1870s, as a general printer, and later became the publisher of the Govan Press. Its founder, John Cossar, was born in Lanarkshire in 1841, and apprenticed as a printer in Biggar. After a period in business on his own account in Carluke, he moved to Glasgow where his business grew. He was the inventor of a folding and pasting machine, but took out no patents.

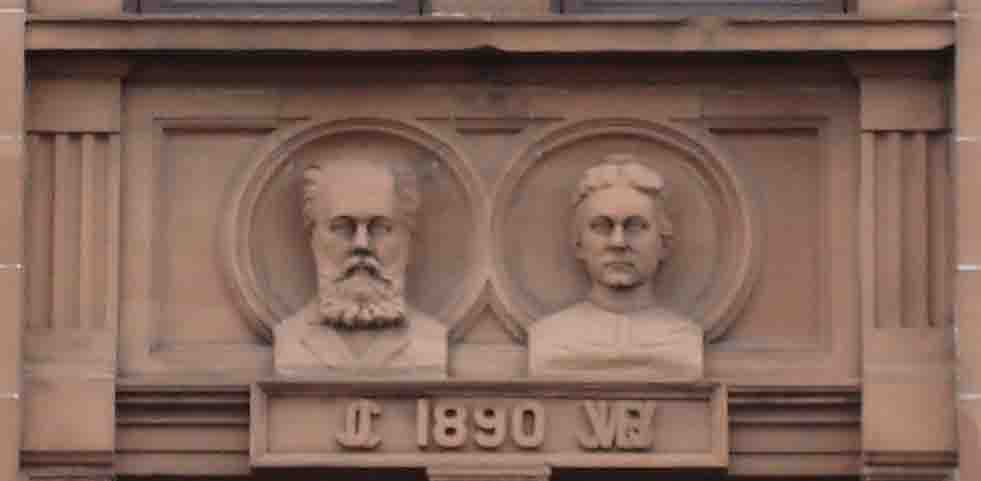

In the 1890s, Tom Cossar was experimenting with adaptations to the ‘Wharfedale’ flat-bed presses used in the family business, John Cossar & Son. The firm had its origins in the 1870s, as a general printer, and later became the publisher of the Govan Press. Its founder, John Cossar, was born in Lanarkshire in 1841, and apprenticed as a printer in Biggar. After a period in business on his own account in Carluke, he moved to Glasgow where his business grew. He was the inventor of a folding and pasting machine, but took out no patents.  After various moves, new premises for the firm were built on the corner of Govan Road and Burndyke Street: the façade of the building still stands, with the busts of Caxton, Gutenberg (misspelled as Guttenberg), Robert Burns, Sir Walter Scott and Mr and Mrs Cossar themselves.

After various moves, new premises for the firm were built on the corner of Govan Road and Burndyke Street: the façade of the building still stands, with the busts of Caxton, Gutenberg (misspelled as Guttenberg), Robert Burns, Sir Walter Scott and Mr and Mrs Cossar themselves.

John Cossar died 1890, aged 49, only six months after the firm moved to Burndyke Street. His wife took over running the business, and in 1891, added Clydebank Press and Renfrew Press to the other two titles published, Govan Press and Southern Press. Mrs Cossar remained an important figure in the business until her death in 1926 at the age of 83. The couple had two sons, Thomas and Andrew, and it was the latter who eventually took charge of the business. Thomas, who had initially served an apprenticeship in the local shipbuilding yards, returned to work in the family business. He continued to use his engineering expertise, experimenting on the firm’s Dawson two-feeder ‘Wharfedale’, successfully converting it into a reel-fed press. According to the Poverty Bay Herald of 10 August 1907 ‘Every week, after the paper had been issued, he would pull a portion of their own machine down and experiment’. The first patent on Cossar’s new machine was taken out in 1899.

Payne & Son of Otley invited Tom Cossar to in Yorkshire to supervise the building of these machines, and in 1903, the first complete machine was shipped to New Zealand: on 29 February 1904, the Wanganui Chronicle reported:

This morning, for the first time, the Chronicle is printed on the Cossar Patent Flat Bed Web Machine, which recently came to hand from the makers, Messrs. Payne & Sons, of Otley, Yorkshire. This machine was specially selected by our Mr J A Young, after a careful and practical inspection of all the best and latest machines suitable for printing a paper like the Chronicle, which the best known builders of the Old Country had to offer. It is, indeed, the first machine of the kind perfected.

This was a single-cylinder machine which printed an eight-page newspaper in two operations, and was followed within two years by a two-cylinder version, the first of which was installed in a Scottish newspaper office. Around fifty machines of this kind, including the press installed in Crieff, were produced before a new model was developed in 1915. Soon after this Payne & Sons became part of the firm of Dawson, Payne & Elliott. Further improvements to the design were made to allow for the printing of larger newspapers.

This was a single-cylinder machine which printed an eight-page newspaper in two operations, and was followed within two years by a two-cylinder version, the first of which was installed in a Scottish newspaper office. Around fifty machines of this kind, including the press installed in Crieff, were produced before a new model was developed in 1915. Soon after this Payne & Sons became part of the firm of Dawson, Payne & Elliott. Further improvements to the design were made to allow for the printing of larger newspapers.

Some idea of the complexity of this task can be seen from another article in the New Zealand press, reporting the installation of a new press at the Poverty Bay Herald in August 1907, almost exactly contemporary with the installation of the Cossar press in Crieff:

- … the machine installed at the Herald works contains over 2000 parts, from very heavy castings to the finer pieces.

- … the framework alone is five tons weight

- … the two cylinders weigh one and a half tons

- … thirty steel and composition rollers are used for receiving the ink from three separate ducts regulated by a series of screws.

The whole article includes a description of the principles on which the machine works, and you can also see the Strathearn Herald’s machine in action. You can also watch the later model B8 and B4 machines in action in New Zealand.

S J Payne worked alongside Tom Cossar: he is quoted in Printing World quoted as saying that:

it was to his benefit when visiting newspaper offices after the war the the Cossar press was held in such high esteem. Newspapers purchased the machine not only because of its reliability but also because of the personal attention which had been given to customers by the late Mr Cossar.

Mr Payne adds: ‘I had the good fortune to work under Mr Cossar. He was a perfectionist and expected a similar standard from all those who worked with him.’

According to Bernard Seward ‘the unique pulsating roar and clatter of the Cossar came to be heard on quiet evenings echoing down the lanes and passageways leading to the premises of hundreds of small town weekly newspapers.’

The machine was so popular because the local printer in every small town, in addition to jobbing work, would usually print a local newspaper on the equipment available, which would involve printing the first side, printing the second side, folding, trimming and collating the sections. This was a laborious way to produce a newspaper, but the efficiencies of the large rotary presses used for the production of national and regional daily papers were out of reach of the small proprietor: not only were the presses costly, they required the production of curved stereotype plates, which led to further costs. Cossar’s invention — a development of the industry standard stop-cylinder ‘Wharfedale’ flatbed press — revolutionised the production of local, and other small circulation papers.

The Cossar printing machine combines the simplicity and economy of a flatbed press, with the convenience of printing direct from type onto a reel of newsprint. It used the existing skills and typesetting equipment available in every letterpress printers, but was reel- instead of sheet-fed, and used a system of compensating rollers to solve the problem of combining an intermittent printing action (the impression cylinder stopping after each impression to allow the reciprocating printing bed to return) and continuous web conversion (folding, slitting). The machine’s technology was ahead of its time and remains a startling and unusual solution to the problem. It made small circulation local papers viable with a technology which remained unchallenged for fifty years: they were produced until 1968 by Dawson, Payne and Elliott.

Cossar machines remained in use for many years longer: in 1976 the John Cossar & Sons left the Govan premises, taking their Cossar presses with them.

Cossar machines remained in use for many years longer: in 1976 the John Cossar & Sons left the Govan premises, taking their Cossar presses with them.

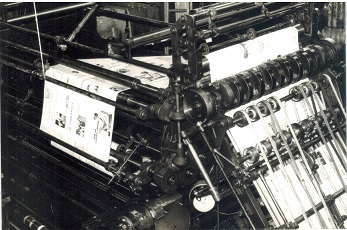

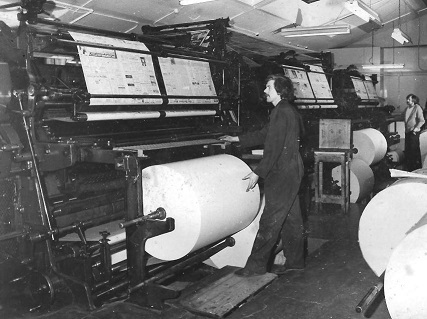

The three Cossars pictured below were some of the last installed. They were used to print the titles published by the Moray and Nairn Newspaper Co Ltd, and were later adapted to work with electronic typesetting systems and polymer plates — shown being loaded into the bed of the machine.

SPRAT is grateful for support from The Watson Foundation

SPRAT is grateful for support from The Watson Foundation